CITBA Arthez offers engineering services for the early level of your projects, whether new equipments or retrofit of existing units. Our expertise in high performance in boilermaking and piping makes us a creative partner for the success of our customers :

• Dimension, calculation, simulation of process equipments

• Simulation, optimization of process and equipments, with Prosim®

• Material choices

• Detail engineering

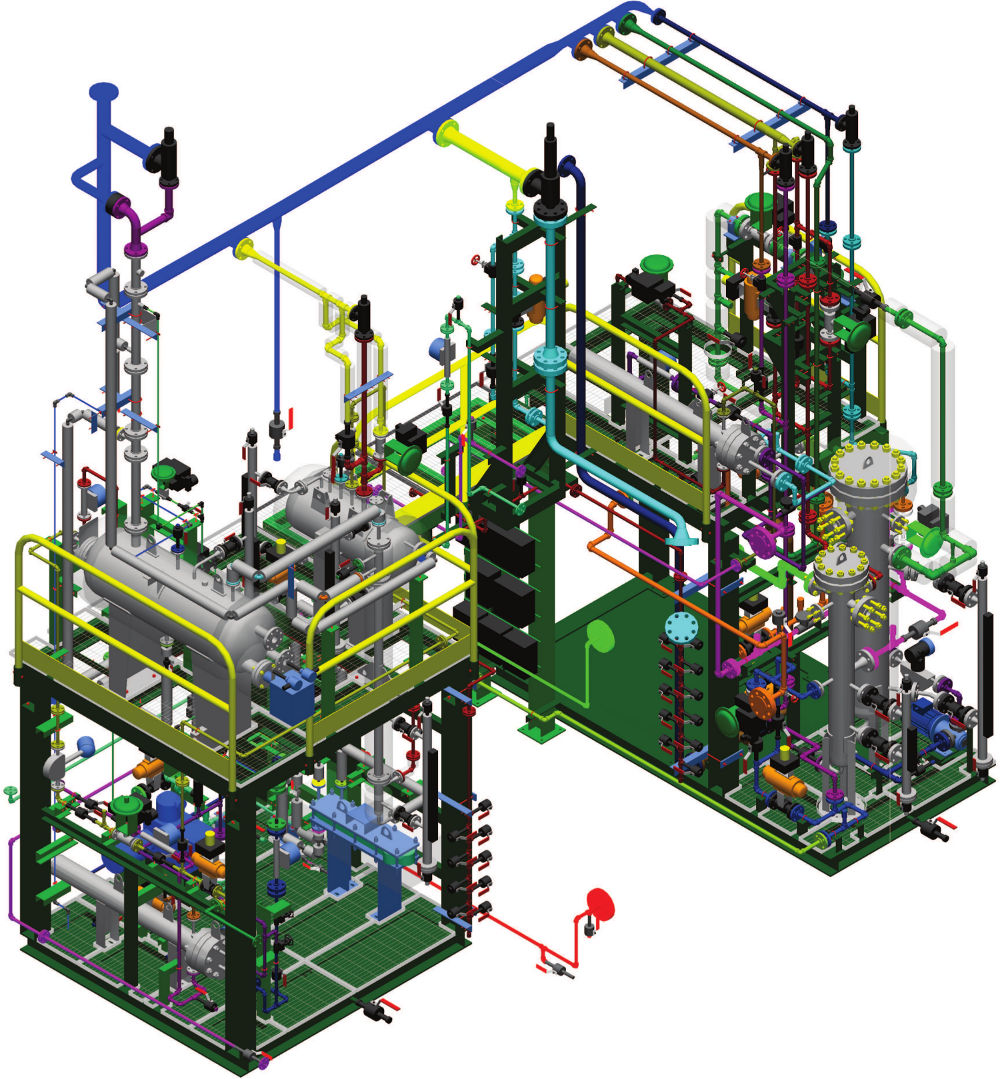

The evolution and the growing complexity of the requirements needs an adaptation of each realization.

Our engineering office designs, tests and approves each of our realizations, which respects of the international technical rules : DESP, CODAP, CODETI, ASME VIII DIV1, PD 5500, ASME B31.3, …

CITBA Arthez has over 40 years experience in boilermaking and industrial piping, in various areas : oil&gas, chemical industry, paper, pharma, surface treatment, agrofood, cosmetic, …

We put this rich experience at the service of our customers, with the specific engineering and manufacturing of complete functional equipments, with boiler-made parts, piping, welding, electricity, automation and instrumentation :

- Heat pump’s patented system, for process gas temperature maintenance

- Pressure filters

- Plate columns

- Manifolds

- Gas treatment units

- Absorbers

- Indirect water-bath reheaters

- Product injection packages

- Waste treatment units in a super-critical medium

- Gas meter station and pressure-reducing station

- Desalters

- Phase separators (manufacturing/test)

- Reactors

- Block valve stations

- Cracking furnaces

- Scraper traps with fast opening’s patented system

We listen to our customers for the realization of high performance boiler equipments, made for critical applications, implying all or part of following requirements :

- Transportation, storage and treatment of sensitive fluids : acids, gas, oil, liquid nitrogen

- Conditions of high temperature, high pressure

- Expertise and control of special materials : carbon steel, refractories, stainless steel, titanium, monel, uranus, light alloys, …

- Expertise, advice and innovation

- Top quality and reliability

CITBA Arthez installs turnkey equipments and realizes the project management of large sets of piping construction on site.

Our well-trained and experienced staff operates on your industrial site, regardless of its location and its risk level : facilities classified for environmental protection, Seveso lower tier, Seveso upper tier, …

We possess the MASE approval (Management Sécurité Santé Environnement).

CITBA Arthez has a strong customer service, with the determination to satisfy and make our customers succeed.

We offer technical support and maintenance services :

- Main turnaround maintenance shutdowns,

- Preventive maintenance,

- Curative maintenance in case of emergency.

These services are proposed on all the equipments we deliver, but also on existing units.

Thanks to the strength of CITBA Group, we are able to support and coordinate multi-skills maintenance operations : electricity / instrumentation, general mechanics, plastics and metals welding, …

CITBA

Pôle 1

ZI de la Geüle

64 370 Arthez de Béarn

France

Tél : +33 559 677 611

Mail : contact@citba.com